Monitor Stand

Now that I have a desk for my laptop, I can setup a permanent work station, meaning that I can have an external monitor. Yup. That was a pretty good news. I love my mac display, but 13 inch is a bit small sometimes.

I bought a Dell U2414H monitor. It’s great. I mean I really have no complaint about that thing, except the stand it comes with. It is pretty chunky. It makes sense though, it has a lot of adjustments, height, rotation, swivel, all these fancy things. Also when you are designing a display for thousands of different people, you need it to fit everyone’s need, be robust and stable. But I don’t need any of those features. My monitor is going to be against the wall anyway so it won’t fall anytime soon. And when I have found a position that I like, I am not gonna move that thing ever again. What I need however, is the space that it takes. I need it back!

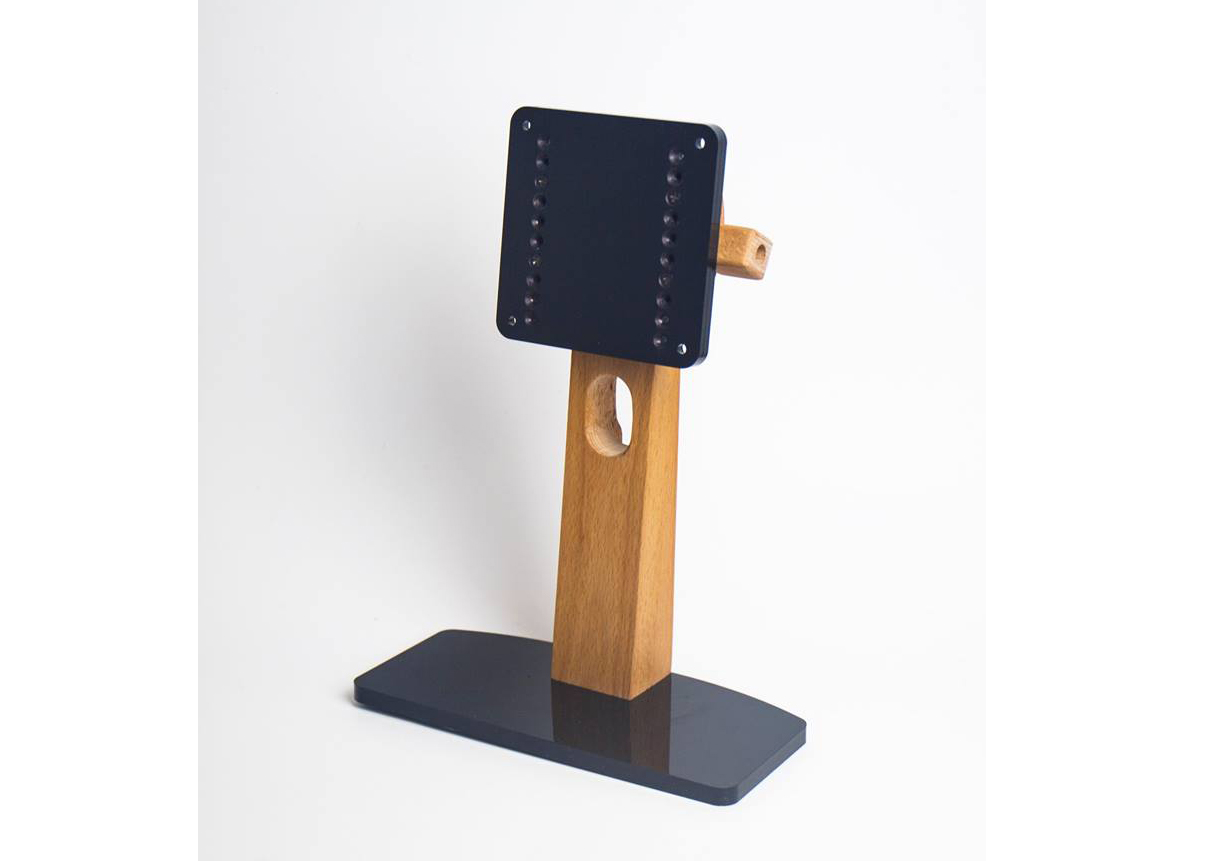

So quite naturally, I designed a new stand for my monitor. It is quite easy knowing that it follows the VESA standard, so a square plate with some holes will do to attach the new stand.

I designed something on solidworks quickly, and soon realised that I had to find a way to make it blend with the monitor’s design. All wood was really looking weird. So I went for a laser cut acrylic base and vesa plate, for strength but mostly so it matches the plastic feel of the monitor. The wood for the post is beech, the same as the desk, so I think it all blends quite well.

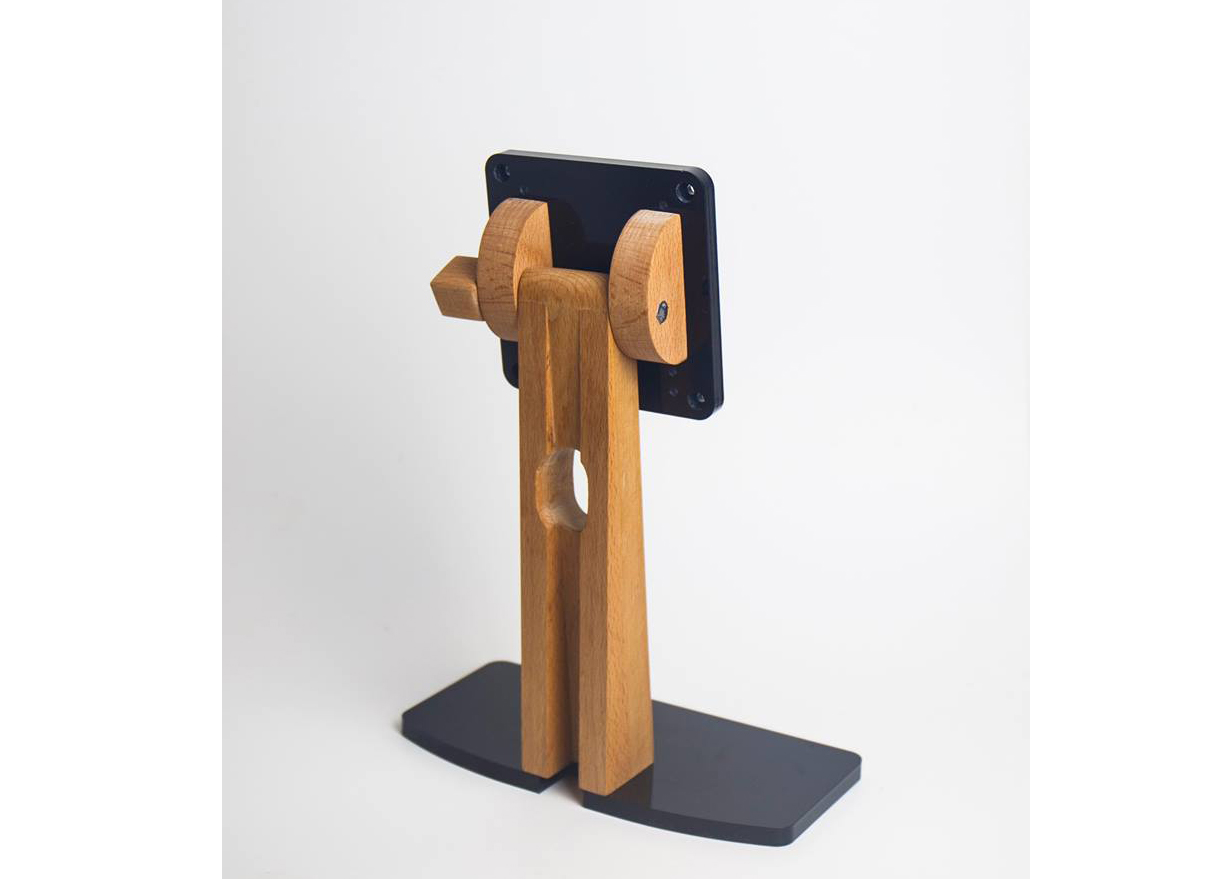

I can still tilt the display to change it’s angle. The profile of the stand is as small as it could be. The display could not be any closer to the wall, the base is quite small, so doesn’t take much space, if any. I went for a design that allowed for cable management. Everything is hidden and looks as neat as possible.

I am not gonna lie, there is nothing that I’d like to do differently for that one. I actually made another one for another external display, and made it exactly the same. Ok, apart from the acrylic plates that I made thinner, 6 mm instead of 8. 8 appeared to be well overkill.

The only thing that could be improved is how tight the rotating bit to change the angle is. At first it was slipping quite a lot, so I had to sand the edges as roughly as I could. Now it doesn’t move anymore, so it’s good. I shouldn't have oiled that part either. Doesn’t help!

SHOW COMMENTS

HIDE COMMENTS